Very high-speed, yet power-saving data communication or global positioning can only be re-established after sleep mode if the solution uses a high-precision, fast-starting 32.768 kHz system clock. Employing a 32.768 kHz silicon oscillator in a battery-powered solution based on hibernation technology can save more than 50 percent power. The specialists at PETERMANN-TECHNIK explain why 32.768 kHz silicon oscillators are taking hold in battery-powered hibernation technology applications and what advantages they offer the user.

Many end products employ hibernation technology, including, for example, wearables, Bluetooth low energy (BLE) based communication units for commercial, industrial, automotive and IoT applications, GPS (commercial and automotive), M2M communication, personal trackers and medical patient-monitoring systems, IoT, smart metering, home automation, wireless and much more.

How does hibernation technology work?

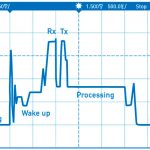

Hibernation technology is predominantly used in positioning applications and in terminal devices that exchange gathered data with a separate receiver via Bluetooth low energy (BLE). In order to greatly prolong the battery life, especially power-hungry parts of the circuitry in these devices, such as ICs for data transfer and positioning, are put into power-saving sleep mode whenever possible. As soon as the user searches for a new destination, or wants to transmit data via Bluetooth low energy, those sleeping parts have to be woken up again and brought back into their high-power working mode as quickly as possible (Figure 1).

Extremely short wake-up saves 50% system energy

For high-speed and energy-efficient data communication, the 32.768 kHz system clock has to be highly precise so that the application can run through the process depicted in Figure 1 at high speed and then immediately be put back into sleep mode.

An imprecise system clock causes the power-consuming process shown in Figure 1 to repeat as many times as needed until the data has been sent from the transmitter to the receiver, say from a wearable to a smartphone. This repetition increases power draw and thus considerably shortens the battery life. Yet, these constant power-consuming synchronizations between the transmitter’s and the receiver’s system clocks become redundant when a high-precision 32.768 kHz reference frequency is provided. A very long stand-alone operating time is a key factor for the transmitter unit’s marketing success. A patient-monitoring device that cannot operate over long periods will hardly be accepted. The user will wonder why he needs to repeatedly recharge his device or change the battery, and will not recommend the product to others, or will even post a negative review on the Internet.

A high-precision system clock has another power-saving benefit in GPS applications: It can prolong the hibernation periods while still maintaining a quick start of less than a second.

How 32.768 kHz quartz crystals and quartz oscillators differ from 32.768 kHz ultra low power oscillators

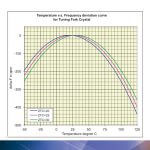

Due to the quartz cut, the temperature stability of a 32.768 kHz quartz crystal – unlike with a MHz quartz crystal – cannot be narrowed by changing the cut angle. Over the temperature range of -40 °C to +85 °C, the most precise temperature stability of a 32.768 kHz quartz crystal is about -180 ppm (Figure 2); that of a MHz quartz crystal, by contrast, is ±15 ppm.

A 32.768 kHz silicon oscillator of the PETERMANN-TECHNIK ULPPO series, for example, which is only 1.5 x 0.8 mm in size, has a temperature stability of ±5 ppm over the temperature range of -40 °C to +85 °C and is accordingly 36 times more precise than a 32.768 kHz quartz crystal. Furthermore, the aging of the ULPPOS after the first year is ±1 ppm, and after 10 years is ±5 ppm. The aging of a 32.768 kHz quartz crystal after the first year is ±3 ppm, and after 10 is much greater than ±20 ppm. Another factor that affects application precision is the frequency stability, where the standard value of a 32.768 kHz quartz crystal at 25 °C is ±20 ppm. A 32.768 kHz quartz crystal therefore yields only a very imprecise system clock, which allows only very slow data communication and, given the repetitions in data communication described above, consumes a great deal of power.

Quartz oscillators at 32.768 kHz are also commercially available. These are larger in size (2.5 x 2.0 mm or 3.2 x 2.5 mm) and use various different technologies. Typical are quartz oscillators in which the 32.768 kHz is produced by dividing a MHz frequency (2.5 x 2.0 mm). Such oscillators consume several milliamperes and are therefore wholly unsuitable for battery-powered solutions.

Other 32.768 kHz quartz oscillators (3.2 x 2.5 mm) are based directly on a 32.768 kHz quartz crystal and consume less power if the frequency precision of the quartz crystal is not compensated by the oscillator IC. The frequency in this case, however, is just as imprecise as that of a 32.768 kHz quartz crystal, where this oscillator has a very slow build-up.

The third solution is based on a 32.768 kHz quartz crystal and an oscillator IC that compensates for the very high frequency precision of the 32.768 kHz quartz crystal, but typically starts very slowly, at around 3 seconds, and therefore necessitates many power-consuming repetitions.

Power-saving solution from PETERMANN-TECHNIK

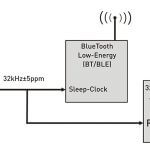

Most Bluetooth low energy solutions employ two 32.768 kHz quartz crystals (one for sleep mode of the BLE IC and one for the MCU clock) and a MHz quartz crystal as reference frequency for the BLE chip (Figure 3). In a typical wearable application, one 32.768 kHz silicon oscillator can be the clock for the sleep mode of the BLE and the MCU simultaneously. This saves an enormous amount of space on the board, since the ULPPO, at 1.5 x 0.8 mm, is only about half the size of the smallest 32.768 kHz quartz crystal, at 1.6 x 1.2 mm, and 85 percent smaller than a low-power quartz oscillator, at 3.2 x 2.5 mm.

Considering the space requirements of a 32.768 kHz quartz crystal, with its two external decoupling capacitors to ground, the ULPPO takes up only 85 percent of the space of a quartz-based solution. The ULPPO can do without decoupling capacitors, since the installed IC filters the supply voltage itself.

Extremely low power draw

Even the standard versions of the PETERMANN-TECHNIK 32.768 kHz silicon oscillators have an extremely low power draw of less than 1 µA at a VDD of 1.8 VDC. To reduce the power draw even further, the output amplitude of the oscillator can be adapted to the IC to be clocked. In this case, VOH can be set within the range of 0.6 to 1.225 V, or VOL in the range of 0.35 to 0.8 V. A PMIC or MCU with a supply voltage of 1.8 VDC requires a VIH amplitude of 1.2 V or a VIL amplitude of 0.6 V. That way, the 32.768 kHz silicon oscillators can be adapted to the MCU and the BLE to optimally save power: This is another major advantage of next-generation silicon oscillator technology, which a 32.768 kHz quartz oscillator does not offer.

High starting reliability

Since 32.768 kHz quartz crystals have very high resistances, they do not always harmonize optimally with the oscillator stages of the ICs being clocked. The quartz sometimes starts oscillating, sometimes not. When it does, it is not always clear why. The negative input resistances of the oscillator stages of the ICs to be clocked often drift wildly, and also capacitively. According to measurements by the specialists at PETERMANN-TECHNIK, more than 25% capacitive scattering is not uncommon. That doesn’t make it any easier to design the optimal circuit for a 32.768 kHz quartz crystal, and there is also a frequency shift in the circuit caused by the tuning sensitivity (in ppm/pF) of a quartz crystal. Using an ultra-low-power 32.768 kHz silicon oscillator not only allows the clocking of several ICs simultaneously, but also eliminates starting/build-up problems and frequency shifts. The upshot: Highest starting reliability under all circumstances, at all temperatures, at all times.

Tremendous cost savings

A PETERMANN-TECHNIK 32.768 kHz silicon oscillator saves two 32.768 kHz quartz crystals and their connecting capacitors, thereby greatly reducing the space requirements on the PCB. This means the application can be served perfectly by a much smaller and cheaper PCB. Furthermore, the costs and effort of development, mounting, control and testing are substantially reduced. Given the lower component acquisition and handling costs, as well as lower component prices, the device manufacturer saves not only power, but also money.

Greener technology for a smarter world

Power-saving design starts with clocking. The PETERMANN-TECHNIK Ultra Low Power 32.768 kHz Silicon Oscillators are an example of how system power can be reduced by 50 percent in devices based on hibernation technology simply by using the right clocks. The experts of clocking specialist PETERMANN-TECHNIK give advice on choosing suitable components from the range of “next-generation clocking” products and offer comprehensive technical support, design-in, and quick sample and batch delivery, thereby ensuring quick time-to-market.

More information under:

SMD 32.768 kHz SOLUTIONS

-

Power draw over time, during a single

pairing process while establishing a

BT/BLE connection

-

Example of a wearable BT/BLE application,

clocked by the Ultra Low Power 32.768 kHz

Oscillator from the ULPPO series by

PETERMANN-TECHNIK

- Illustration 1: Temperature behaviour of conventional 32.768 kHz crystals